- NAME:Reactive

- CLASS:Reactive Dye Ink

- TEL:+86 591 83303835

- FAX:+86 591 88201182

- PHONE:Wechat/Whatsapp +86 13313769052

- E-MAIL:sales04@obooc.com

- Website:www.indelibleink.com.cn

- Website:www.aobozink.com

Ink Top Feature:

Fast Speed Printing

Vivid Color

Customs fabric printing

Softer feeling and more flexible

Unfading in long time hand washing or machine washing

Ink Introduction and suitable application

Reactive Ink - This ink is the mostly used ink in general textile industry. It has almost the

same color density as screen print colors and it is especially suitable for home textiles &

fashion fabrics. It is used for cotton , silk or even wool. Post printing, it has to be steamed

at +/-102℃ for achieving high quality of colors & fastness.

Acid Ink - It is used for general sportswear such as swimming suits etc made out of NYLON

LYCRA or fabrics from Animal fibre such as wool & silk. Though it offers bright and fresh colors

like reactive inks, but due to higher flexibility of Reactive inks, they are preferred more over acid

inks until unless the production is restricted to only exclusive fabric like silk or nylon. Also high 'ultraviolet light resistance' can be obtained by steaming process like in case of reactive inks.

Disperse Dye Ink - It is used for polyester and good for Home textiles, fashion wear,

sportswear & also flag printing. There are various ways for post printing process for Disperse

inks depending on the purpose of use.

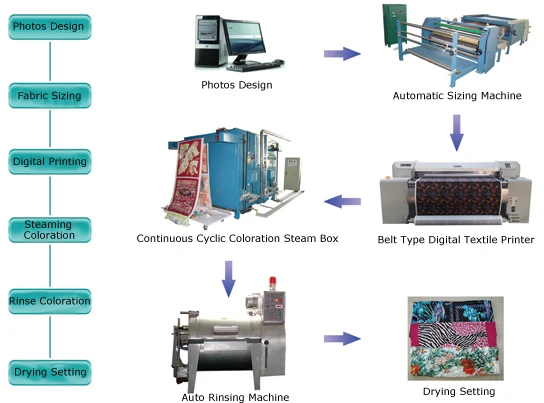

Direct Digital Textile Printing Process